-40%

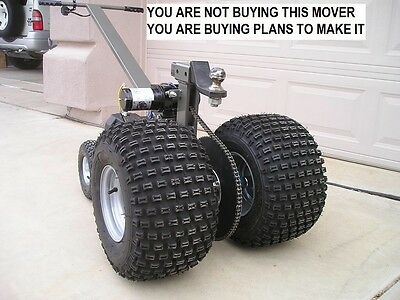

TRAILER MOVER “PLANS”- 12V HEAVY DUTY Version, Dolly Electric

$ 14.75

- Description

- Size Guide

Description

BUILD THIS TRAILER/POWER MOVER FOR LESS THAN 0THIS LISTING IS FOR ONE SET OF PLANS

NOTE- (IF YOU WANT TO SAVE .00 OR MORE, PURCHASE THE EMAIL VERSION)

SEARCH EBAY FOR ITEM: 272813706020, OR, GOOGLE SEARCH: "MOVER PLANS EMAIL")

YOU ARE PURCHASING ONE SET OF "PLANS"

THIS MOVER HAS A SLIGHTLY HEAVIER LOAD CAPACITY THAN MY BASIC MOVER

BUILD YOUR OWN CUSTOM POWER MOVER

FEATURES AND SPECIFICATIONS:

READILY MOVE TRAILERS UP TO 6000 LBS, 10000 LBS ON HARD FLAT SURFACES

SUBSTANCIAL SOLID STEEL FRAME WEIGHS 55 LBS

FRAME AND AXLE CAN CARRY TONGUE WEIGHTS EXCEEDING 1000 LB

USE IT ON DIRT, GRAVEL, CONCRETE OR ASPHALT

POWERED BY A 3000-3500 LB ATV STYLE WINCH

MAXIMUM SPEED (UNLOADED)~30 FT/MIN

MINIMUM SPEED (FULLY LOADED)~12.7 FT/MIN

3000 LB WINCH PROVIDES 680 LB MOVER FORCE AT 50 PERCENT LOAD, 1360 LB AT FULL LOAD

WINCH BRAKE KEEPS MOVER FROM ROLLING WHEN POWER IS REMOVED

EASILY MOVED, FREE-WHEELS WITH WINCH DECOUPLED

RECEIVER STYLE HITCH ALLOWS USE OF DIFFERENT HEIGHT BALL MOUNTS

(Just raise the handle, scoop up the trailer coupler with the hitch ball, lower the handle and you're ready to go.)

A 12 VOLT DEEP CYCLE LEAD ACID BATTERY PROVIDES THE MOVER WITH PLENTY OF ENERGY

HANDLE ROTATES VERTICALLY TO MINIMIZE GARAGE STORAGE SPACE REQUIRED

MECHANICAL COMPONENTS INCLUDE SPROCKETS, HUBS, BEARINGS, CHAIN, AXLE, TIRES, RIMS AND WINCH

PLANS INCLUDE:

DETAILED ASSEMBLY INSTRUCTIONS

DETAILED COMPONENT LIST WITH SUPPLIERS AND PRICES

DETAILED LIST OF STEEL COMPONENTS

8 PAGES OF ASSEMBLY DRAWINGS

APPROXIMATE COST BREAKDOWN:

WINCH ............................................................................5.00

BEARINGS, AXLE, CHAIN, SPROCKETS....................... 9.00

TIRES AND RIMS ..............................................00-5.00

STEEL..............................................................................00

BATTERY AND CASE .........................................................00

MISC........................... ......................................................00

* (Prices will vary depending on the particular selection of components and steel availability. Prices shown typically do not include shipping)

Feel free to ask me any questions regarding these plans.

This power mover is a heavier duty version of my standard mover. It provides 37 percent more force and moves 37 pcrcent slower due to different gearing. Since it moves slower it is easier to control with a heavy trailer during starting and stopping. It also has heavier axle bearings. It uses the same axle and related hardware. The version you see in the above pictures has pneumatic tires on the rear for use on grass and other soft surfaces. The plans you will receive will include drawings for the pneumatic tire version as well as an option of for using hard rubber casters as on the standard mover. The cost of parts for the heaven duty version is slightly more than the standard mover.

It both pushes and pulls with the flip of a switch, and, when you disengage the geared winch it can quickly be rolled to where you want it. The ball mount is interchangeable which allows you to match it to your trailer height. In addition, the handle rotates to a vertical position for storage (see picture).

To change directions with the pneumatic tire version, you lift the pneumatic tires off the ground using the long handle, rotate the mover and then set the tires back down.

The construction of this mover is fairly easy. Once you have all the parts you can build it in a weekend. It does require reasonable welding skills and the ability to understand mechanical drawings. There are no difficult machining operations. A chop saw or band saw and drill press are the only heavy tools required. The difference between the HD and Standard version is the HD version has stronger axle bearings and moves a little slower due to different gearing and thus works a little better for heavier trailers. Other than that the frames are a little different to accommodate the different gearing and axle bearings. This mover will not be quite as easy to build as the standard mover in that the frame requires more steel and more attention to axle bearing alignment as well as some sprocket modifications not required on the standard mover.

The mover may be used on slight inclines (up to 6 percent) but it is not recommended for heavy trailers exceeding 3000 lbs on other than flat or near flat surfaces. On loose surfaces the selection of the ball mount should be made to provide all the trailer tongue weight on the drive wheels.

https://www.youtube.com/watch?v=JwVq1hVFCV4