-40%

(pack) Piston packing K15 PU/NBR ID 15mm-250mm (choose dimensions)

$ 0.66

- Description

- Size Guide

Description

Welcome to our oil seal store. Huge amount of different dimensions and materials are on stock!! Don´t hasitate to contact us. We also have o-ring store, bearing store,chain store,hydraulic and pneumatic seals store, belt store, etc - we can send together.

Most of oil seals are on stock, so we are usually shipping within 2 bussiness days.

Longer handling time 10-20 days occures just on sold out items.

We can also use UPS express shipping. Shipping rates are: UPS to USA

30USD,

UPS to Europe, U.K, Germany, France

20USD,

UPS to N.a S.America, Canada, Mexico, Brazil, Asia, China, Japan, Australia

50USD

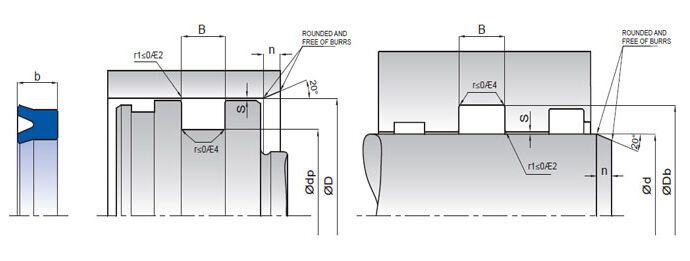

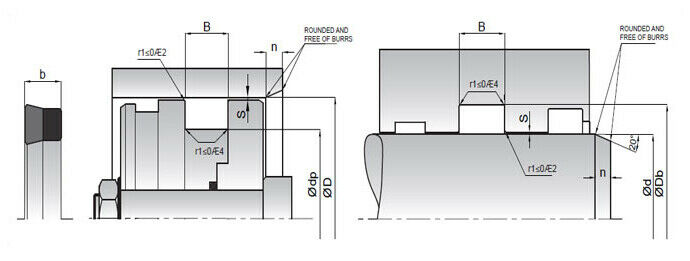

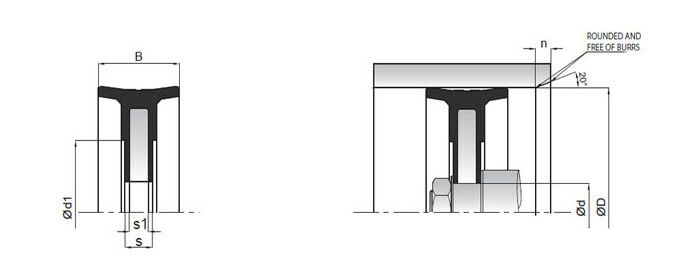

K15 is a two piece double acting sealing set which consists of a special designed polyurethane seal ring and an o-ring as energizing element.

PRODUCT ADVANTAGES

• High static and dynamic sealing effect

• Low axial housing heights

• Simple groove design , one-piece piston possible

• High abrasion resistance

APPLICATION

Light to medium duty industrial machinery ,

MATERIAL

CODE

NBR

70 SHORE A

NB7001

PU

95 SHORE A

PU9501

OPERATING CONDITIONS

MEDIA

Mineral oils (DIN 51524)

HFA ve HFB

HFC

TEMPERATURE

-30°C +100°C

+5°C +50°C

-30°C +40°C

PRESSURE

≤250 Bar

≤250 Bar

≤250 Bar

SPEED

≤0.5 m/sn

≤0.5 m/sn

≤0.5 m/sn

Note: The above data are maximum values and cannot be used at the same time.

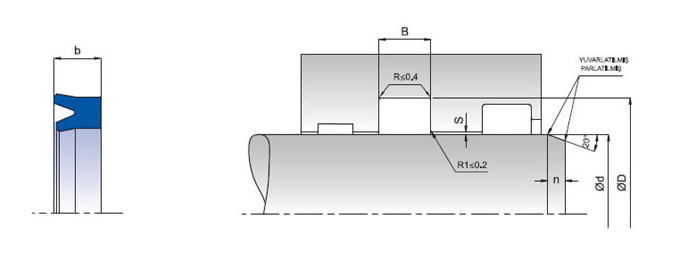

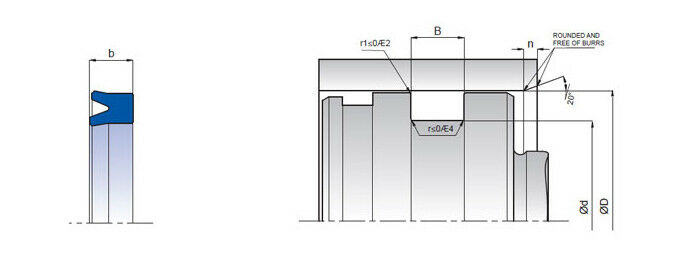

ROUGHNESS SURFACE

Ra

Rmax

Sliding Surface ØD

≤0.4 μm

≤3.2 μm

Groove Base Ød

≤1.6 μm

≤6.3 μm

Groove Flanks B

≤3.2 μm

≤16 μm

Note: It is recommended to have 50% to 90% of the working surface material contact area value .

INSTALLATION

Easily assembled on one-piece piston. It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation the sealing element must be oiled with system oil.

NOTES

It is recommended to use with two piston guide rings in long stroke cylinders , one guide ring in short stroke and under low radial loads. The permissible sealing gap values of K15 piston seal is given in the below table.

PERMISSIBLE SEALING GAP

B (mm)

Smax (mm)

3.2

0.25

4.2

0.25

6.3

0.3

8.1

0.3

Note: The largest sealing gap value occurring on the non-pressurized side of the seal does have a vital importance for the function of the seal and in this respect it is quite important to use the S value lower than the above indicated numbers.